How Do Screw and Nash Liquid Ring Vacuum Pumps Perform with Various Process Fluids?

In the arena of business vacuum systems, screw vacuum pumps and nash liquid ring vacuum pumps are popular technologies used for managing various manner fluids.

In the arena of business vacuum systems, screw vacuum pumps and nash liquid ring vacuum pumps are popular technologies used for managing various manner fluids. These pumps are essential in industries consisting of chemical processing, food manufacturing, pharmaceuticals, and lots of others that require efficient vacuum solutions. But how properly do these pumps perform whilst running with one-of-a-kind varieties of fluids? In this blog, we can explore how both forms of pumps cope with numerous process fluids and discuss their particular functions, benefits, and boundaries.

What Are Screw Vacuum Pumps?

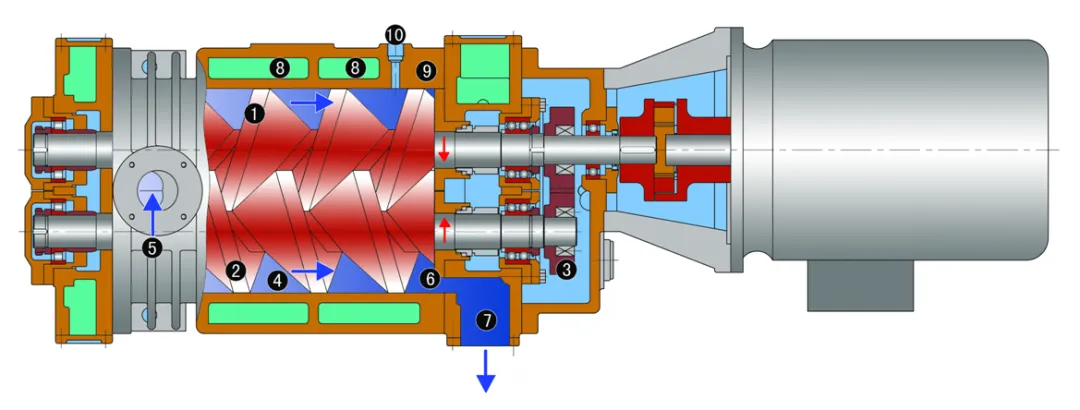

Screw vacuum pumps are fantastic displacement pumps that use interlocking screws to create a vacuum. These pumps are known for his or her efficiency, durability, and ability to handle dry, non-corrosive gases with out the want for lubrication. Screw vacuum pumps are generally utilized in packages in which a non-stop drift of fuel is wanted. However, their performance varies extensively relying at the sort of procedure fluid being dealt with.

How Do Screw Vacuum Pumps Perform with Gas and Dry Fluids?

When it involves dry gases or vapor programs, screw vacuum pumps carry out pretty well. These pumps are designed to handle low- to medium-vacuum ranges and can create a strong vacuum without the need for complex renovation processes. They are green for processing non-condensable gases including air, nitrogen, and other mild hydrocarbons. Screw vacuum pumps are ideal in applications that demand minimum risk of infection, consisting of in food processing or pharmaceutical programs.

However, the performance of screw pumps may be influenced by means of the properties of the gasoline. For instance, gases that are heavy, dense, or incorporate contaminants may additionally pose challenges, requiring additional filtration structures or changes to the pump’s design.

What Are the Advantages of Screw Vacuum Pumps in Gas Applications?

Energy Efficiency: Screw vacuum pumps use less power in comparison to different vacuum structures for dry gases, making them price-effective in lengthy-term operations.

Minimal Maintenance: Since those pumps do no longer require lubrication or water-cooling, they're low preservation.

Stable Vacuum: They offer a constant and strong vacuum performance with minimal fluctuations, making sure clean operation.

However, screw vacuum pumps are not suitable for fluids containing full-size quantities of moisture or condensables, which can result in corrosion and operational inefficiency.

How Do Nash Liquid Ring Vacuum Pumps Handle Various Fluids?

Nash liquid ring vacuum pumps are broadly utilized in industrial programs where fluids might also include moisture, corrosive elements, or want to be handled in a far better manner. Unlike screw pumps, nash liquid ring vacuum pumps make use of a liquid, commonly water, to shape a seal inside the pump’s casing, which lets in them to handle moist or moist gases effectively. These pumps are mainly beneficial in programs where fluid managing requires the ability to transport each gases and liquids concurrently.

These vacuum pumps are maximum normally utilized in applications together with vacuum distillation, waste water treatment, and other strategies wherein a stable vacuum is needed despite the presence of moisture. Nash liquid ring vacuum pumps are known for his or her ability to handle a wide form of fluids, beginning from gases to liquid-laden vapors, without being damaged by means of the fluid’s composition.

How Do Nash Liquid Ring Vacuum Pumps Perform with Wet and Corrosive Fluids?

One of the important thing benefits of nash liquid ring vacuum pumps is their capacity to handle wet fluids, making them ideal for industries in which beverages or condensates are regularly encountered. Whether the fluid is water vapor, ammonia, or other chemicals, those pumps can accommodate a wide variety of fluids with out risking damage to the machine. The liquid ring in the pump now not handiest gives sealing but also allows to wash away any contaminants or solids that would otherwise clog the gadget, which is not the case for screw vacuum pumps.

In instances in which corrosive gases or beverages are concerned, nash liquid ring vacuum pumps are designed with substances which can resist the chemical properties of the fluids being treated. Their capacity to method harsh chemical substances and fluids makes them useful in industries like chemical processing, wherein toxic or corrosive substances are common.

What Are the Benefits of Nash Liquid Ring Vacuum Pumps for Wet Applications?

Versatility: These pumps can take care of each gases and beverages, making them noticeably adaptable to specific process fluids.

Durability: Due to their sturdy design, nash liquid ring vacuum pumps can handle corrosive and abrasive fluids with out dropping overall performance.

Cost-Effective: These pumps are regularly extra less costly to preserve, in particular in packages that involve wet gases, because they do not require complex structures to deal with condensation.

However, nash liquid ring vacuum pumps may not be the exceptional option whilst dealing with dry gases or exceptionally viscous fluids, as their performance can decrease below these conditions.

Which Pump Is Best for Your Application?

Both screw vacuum pumps and nash liquid ring vacuum pumps provide unique blessings depending at the kind of process fluid worried. Here are some key elements to recollect whilst choosing the right pump for your needs:

Dry vs. Wet Fluids: If you're coping with dry, non-corrosive gases, screw vacuum pumps are an splendid desire due to their electricity efficiency and minimal upkeep necessities. On the other hand, in case your utility involves moist or corrosive gases and drinks, nash liquid ring vacuum pumps are more suitable because of their potential to handle such fluids accurately.

Viscosity of Fluids: For excessive-viscosity fluids, nash liquid ring vacuum pumps are better perfect, as they can handle the thicker nature of these fluids without issues. Screw vacuum pumps, alternatively, can also battle with viscous fluids and will require modifications or additional additives.

Energy Efficiency: If reducing electricity consumption is a top precedence, screw vacuum pumps are greater efficient in applications that most effective require the handling of gases, as they use less electricity as compared to nash liquid ring vacuum pumps.

Conclusion

Both screw vacuum pumps and nash liquid ring vacuum pumps offer distinct blessings primarily based on the sort of fluids they may be predicted to handle. Screw vacuum pumps excel in dry fuel packages, supplying strength efficiency and occasional protection, while nash liquid ring vacuum pumps are the go-to desire for packages that involve moist, corrosive, or viscous fluids. By know-how the specific needs of your system fluids, you could make an knowledgeable selection and pick out the pump in order to optimize overall performance and efficiency on your machine.

What's Your Reaction?

.jpg)

.jpg)